Winter Market is a 15-week-long partner project involving research, ideating, and constructing a houseware product using reclaimed and recycled materials while staying under a budget of $100.

Phase One: Discover & Define

Duration: Five weeks

Tools Used: Ethnographic style research, 4 A's, Euler diagram, Mapping

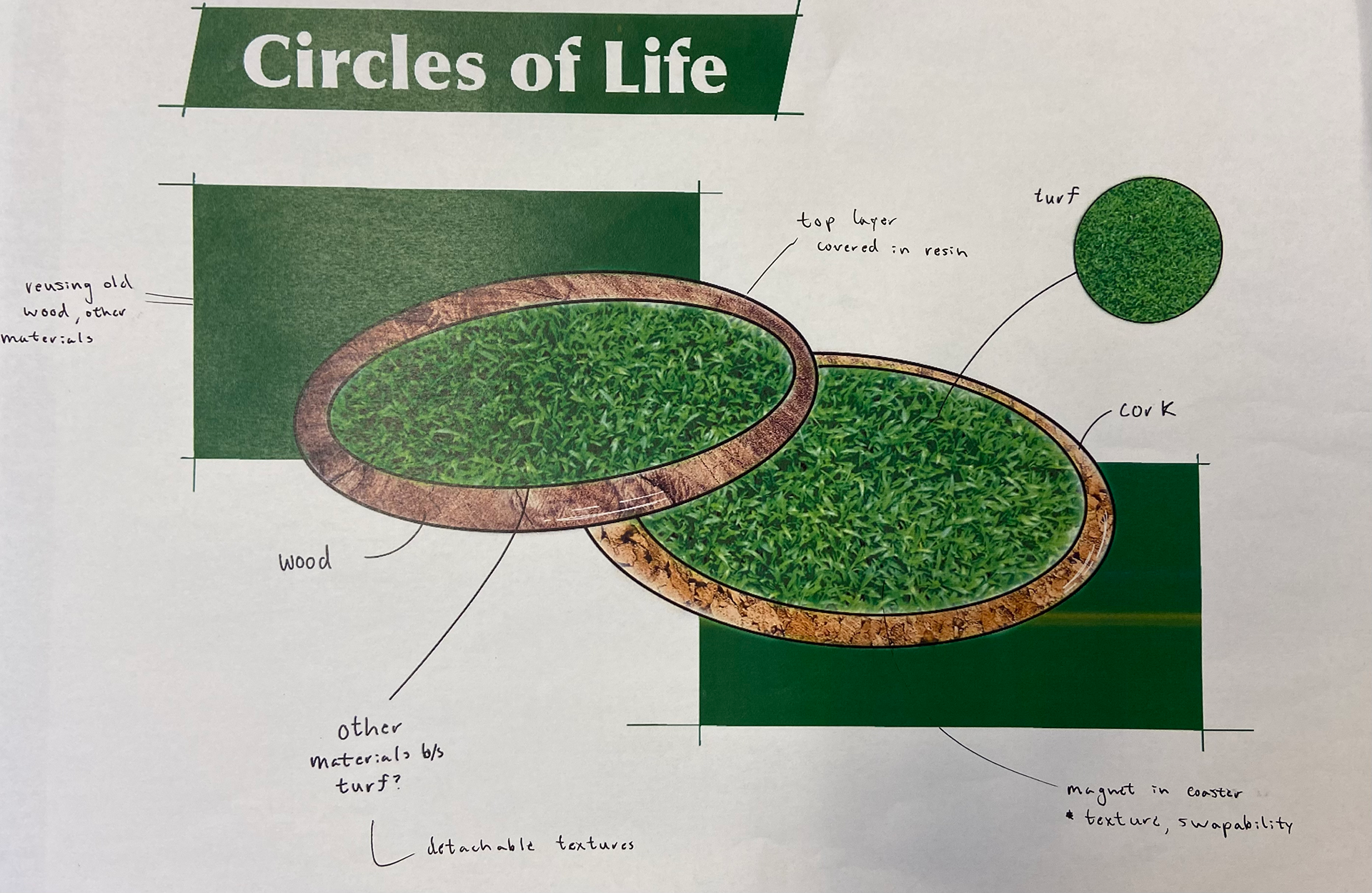

The final product was a set of coasters with a stand made from reclaimed wood and the use of wood stain, linseed oil, and paint

It started with developing team objectives, a practice field assignment, and narrowing down ideas

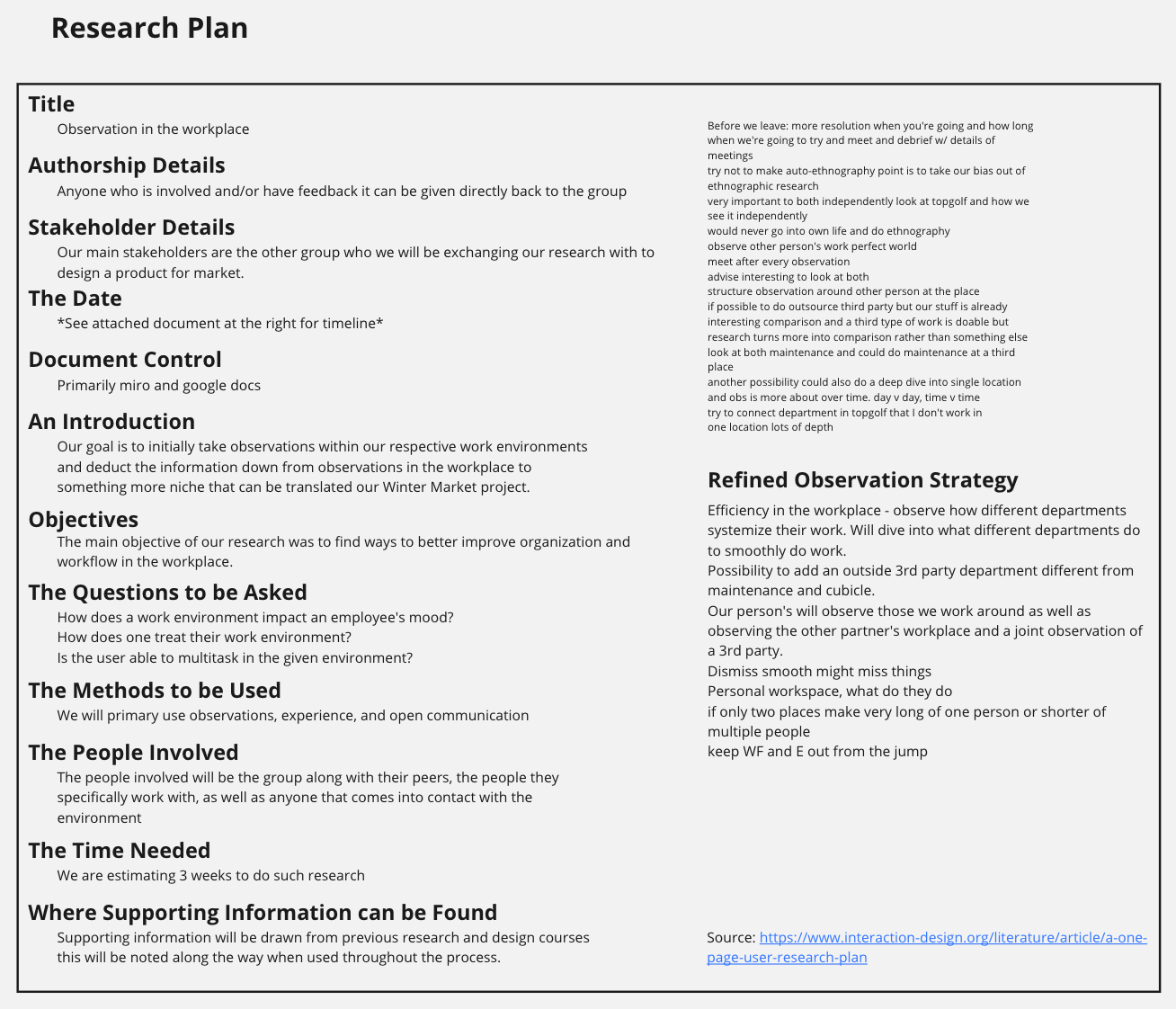

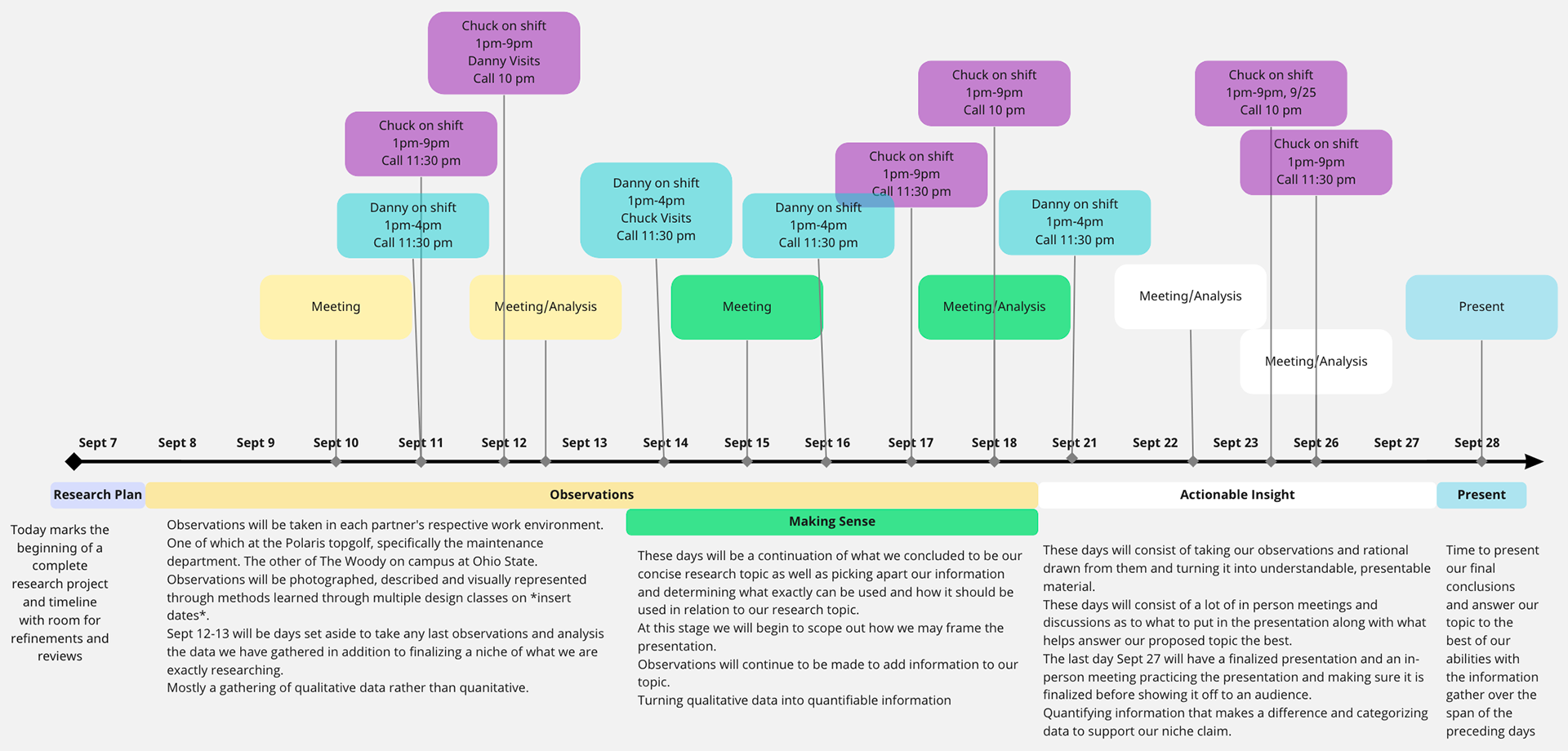

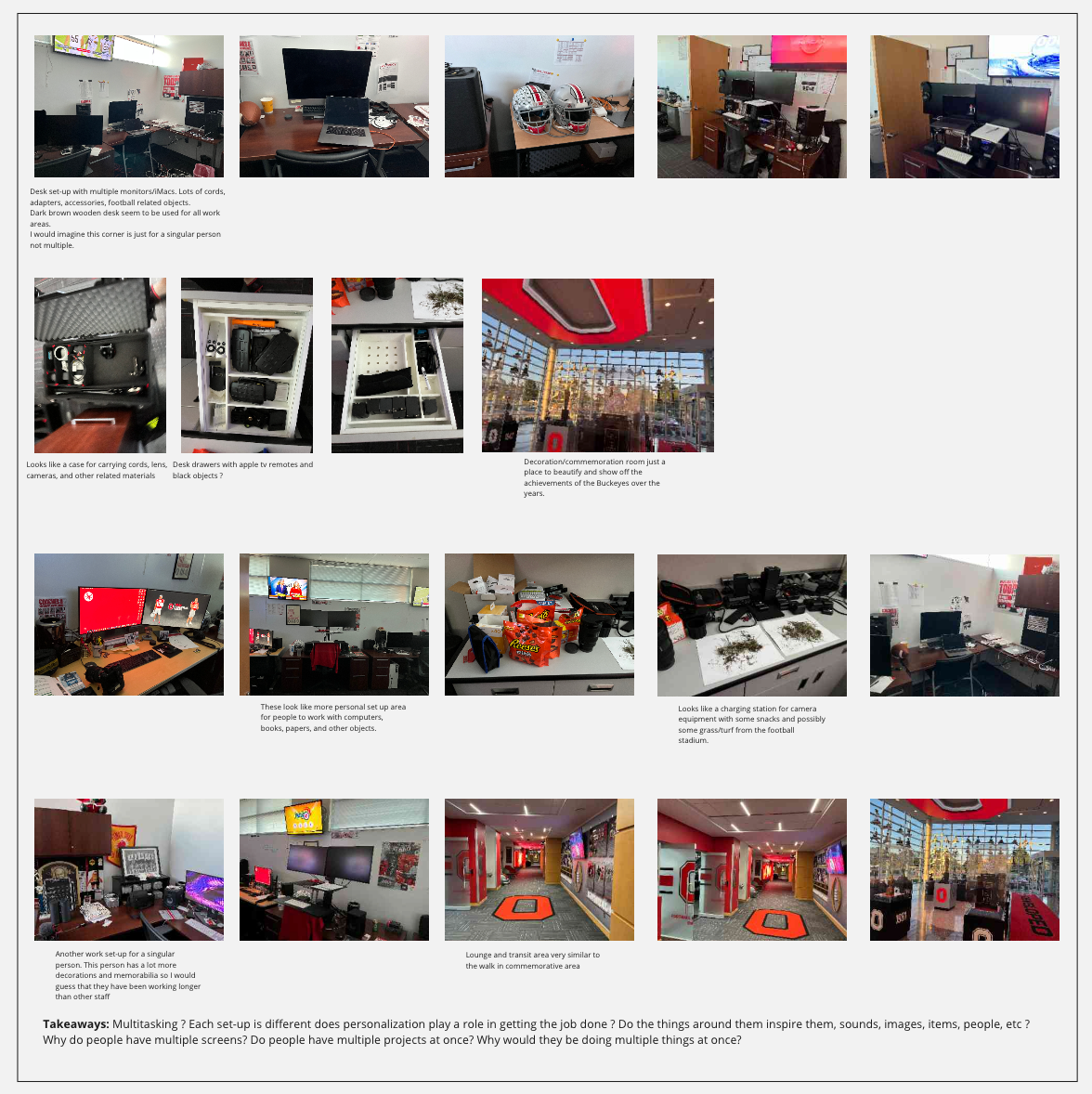

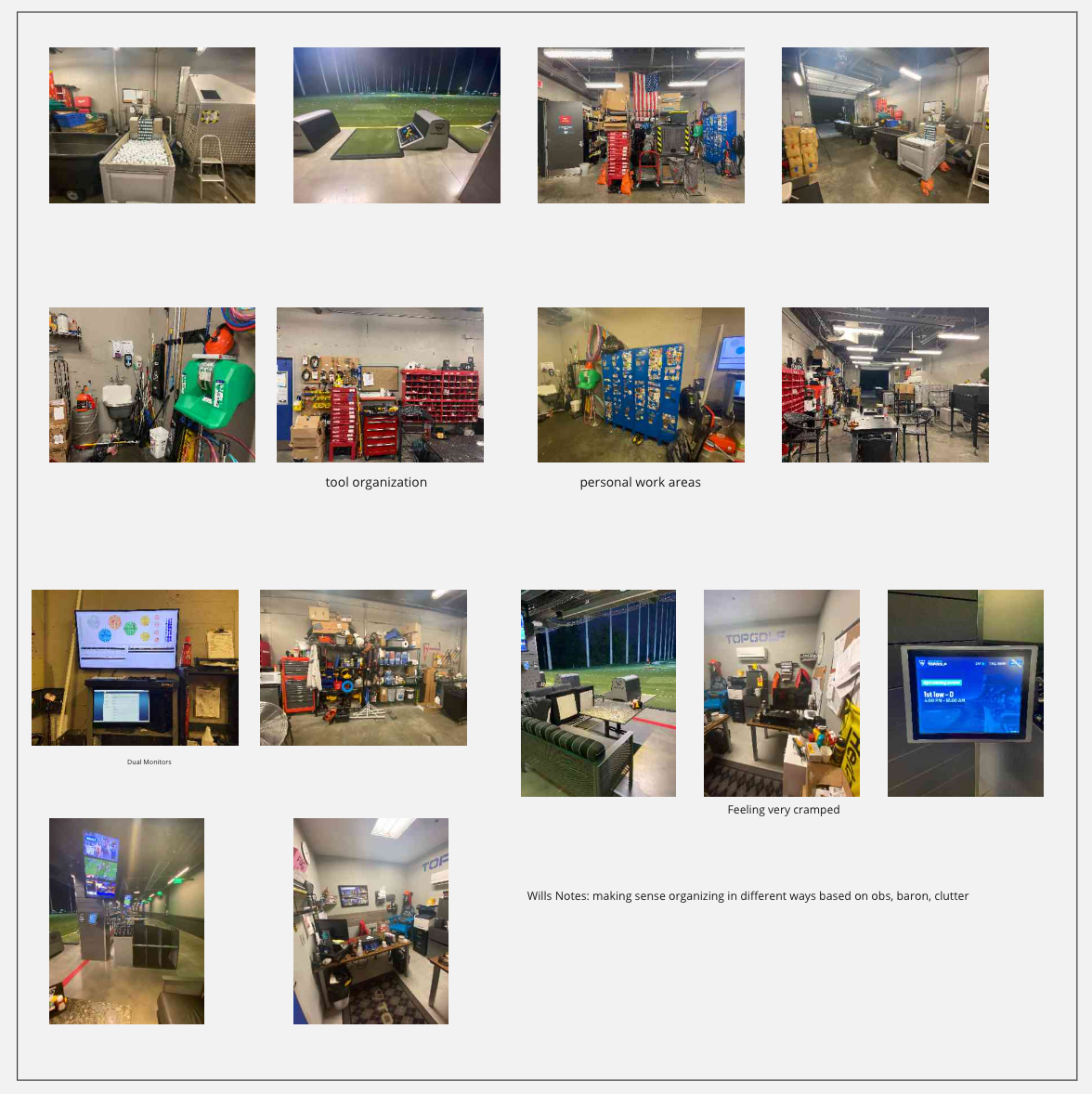

The team continued narrowing research ideas and came up with a topic of interest for both partners. A research plan was developed and the agreed-upon topic at first was researching efficiency within both of our respective workplaces

A timeline was developed and the team began image gathering to take their first steps toward doing ethnographic style research

At this point in time, the team struggled to discover what they needed to do and pivoted. The new research topic became soccer, the people playing, watching, scouting, and everything else surrounding it began to be observed

The first tool was used to help analyze everything the team saw using the 4 A's. Four A's is a way the observer can break down and begin to make connections between what they're looking at in regards to actors, actions, atmosphere, and artifacts

Research continually had to be looked at through different perspectives so the team worked on putting information into a Euler Diagram and looking at the research through a different lens and started to find insights

The team found there was a direct correlation between goals being scored and what kind of actions were happening from different people, in different situations

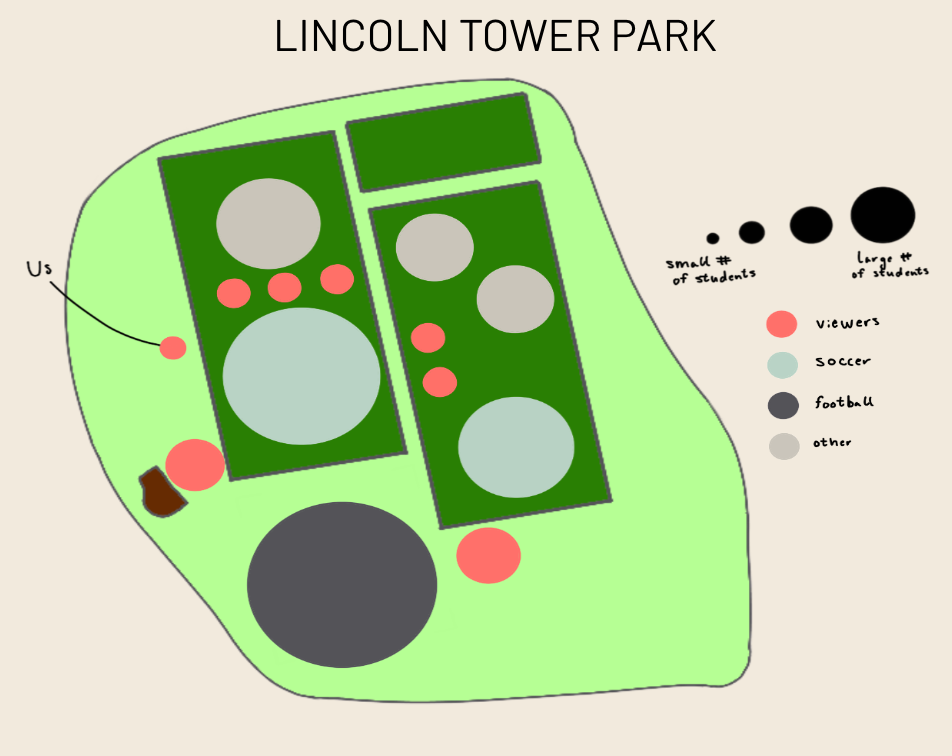

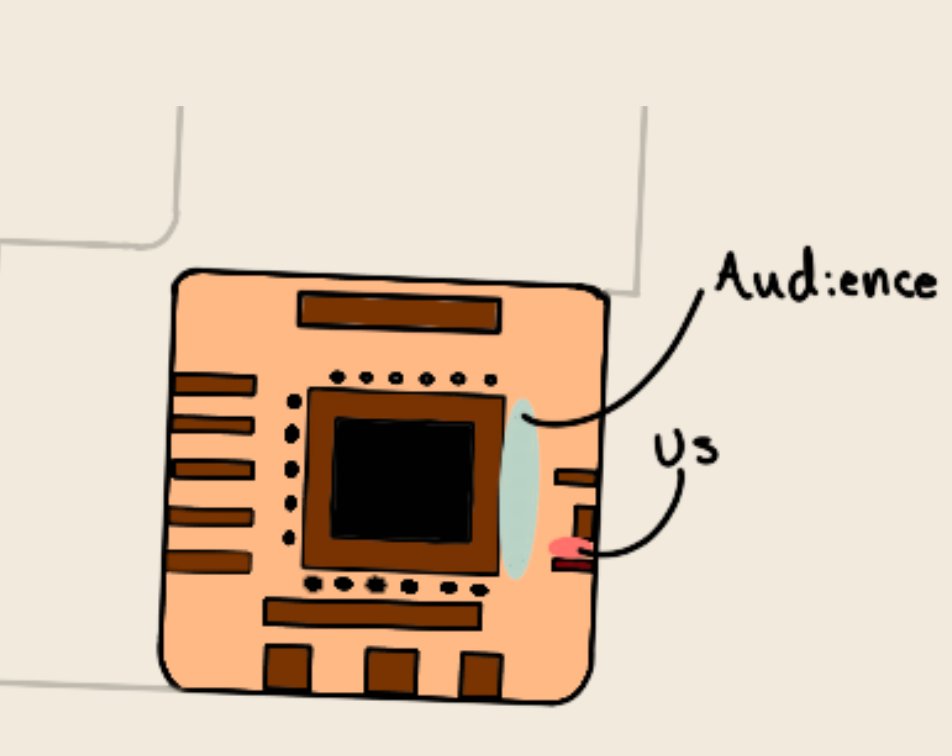

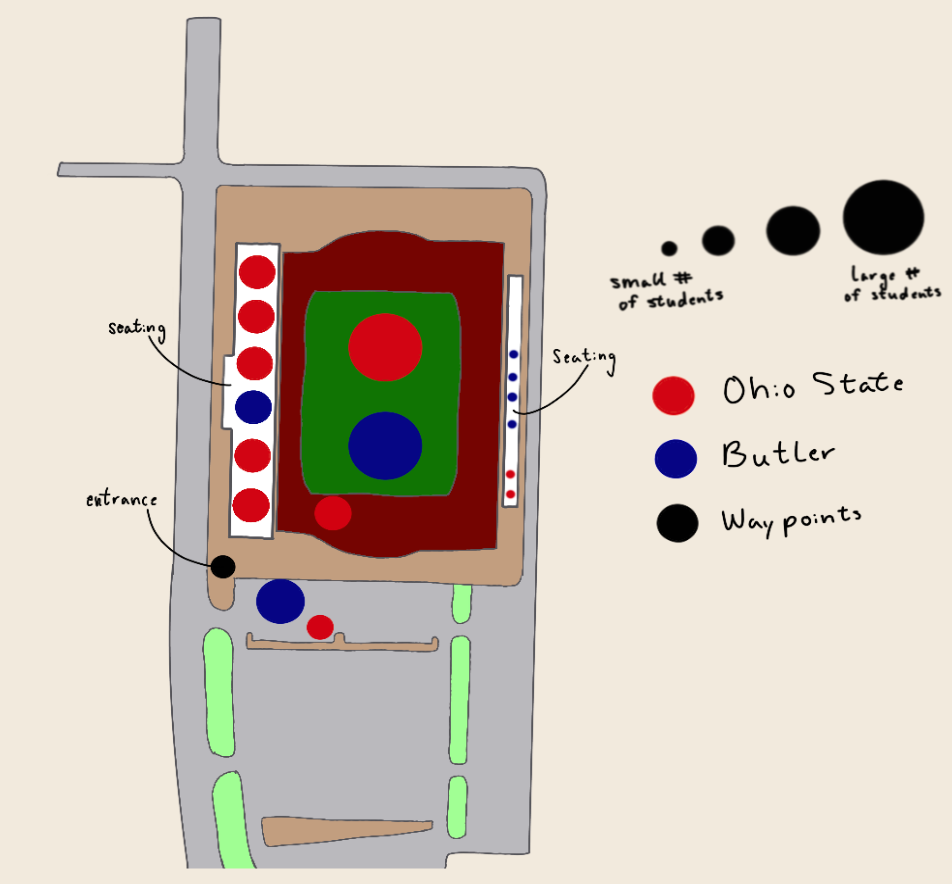

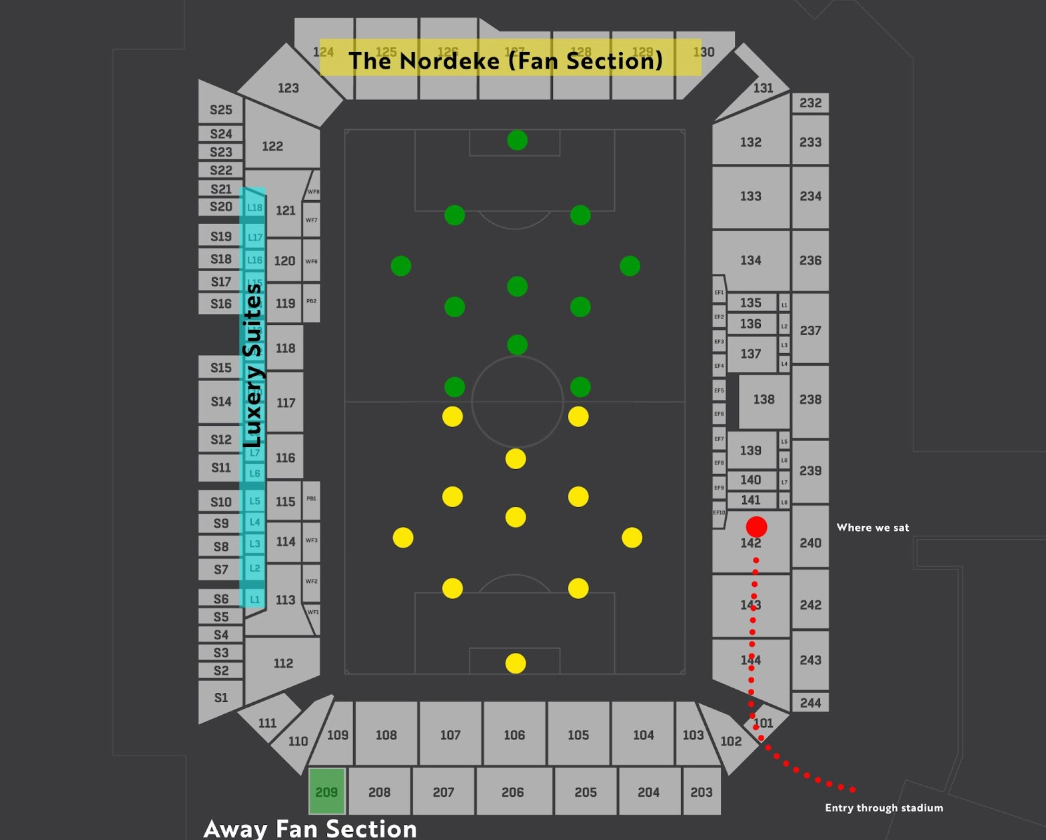

Through continued research and analysis the team began conducting mapping between what type of people were where when watching soccer including college-level games, rec soccer, professional soccer, and at a sports bar

Over the five-week course, research was done and the team was able to present four actionable insights that were to be used to segway into the ideation phase for developing a houseware product

Phase Two: Define & Develop - Duration: Five weeks

Tools Used: Sketching, Brainstorming, Market analysis, User profiles

As part of the Winter Market project, after doing research each set of partners had to swap research with another group. So, the team developed a new schedule for this phase of the project and began ideating with regard to research done on small spaces and restorative actions

The team started by reviewing what research they would be receiving and where to go from there

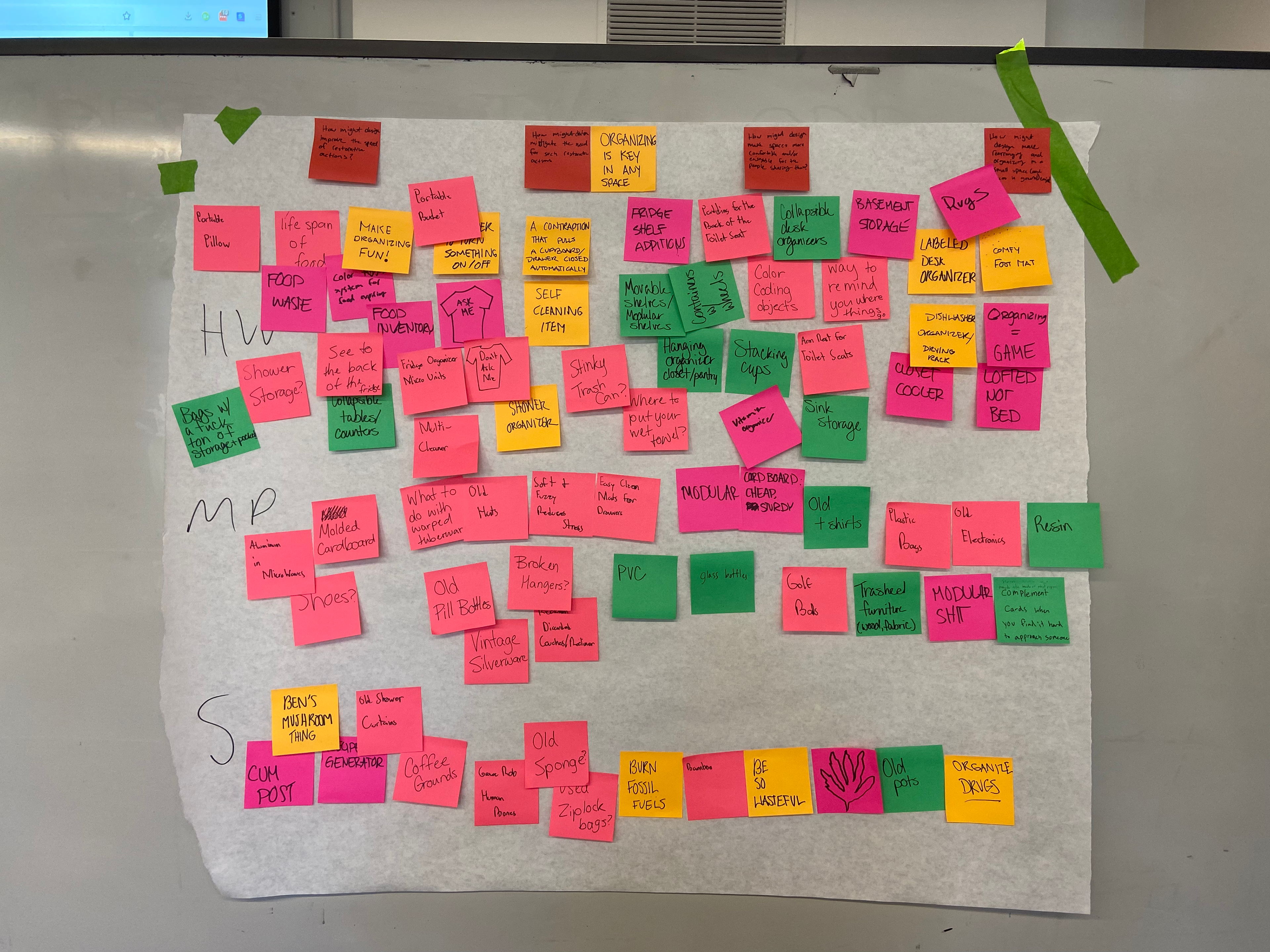

From an initial review, a group brainstorm between six classmates was held to generate ideas within nine different subsections. From there the goal was to come up with roughly 16 initial concepts and as time goes on to eliminate half and push the ideas that were still alive

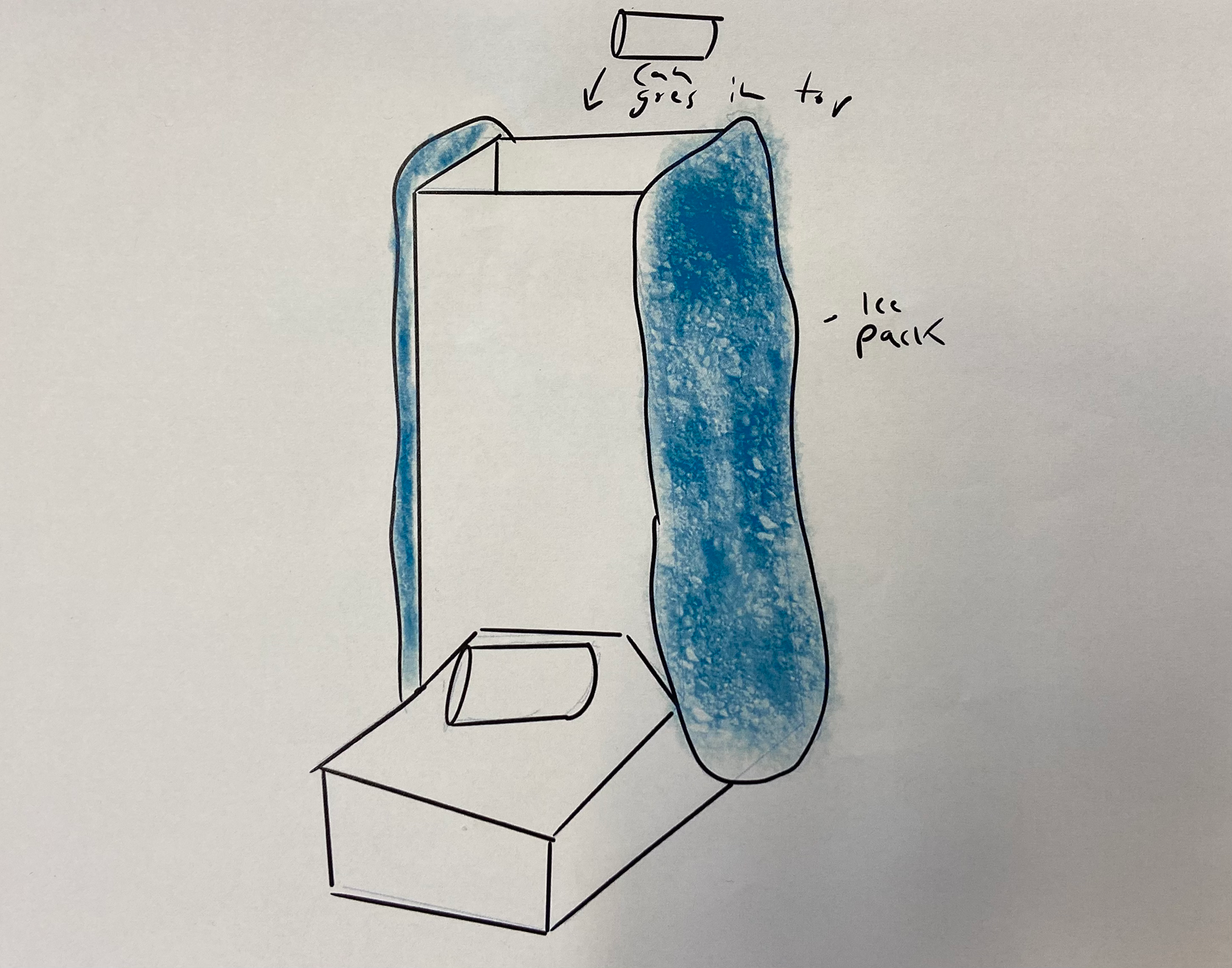

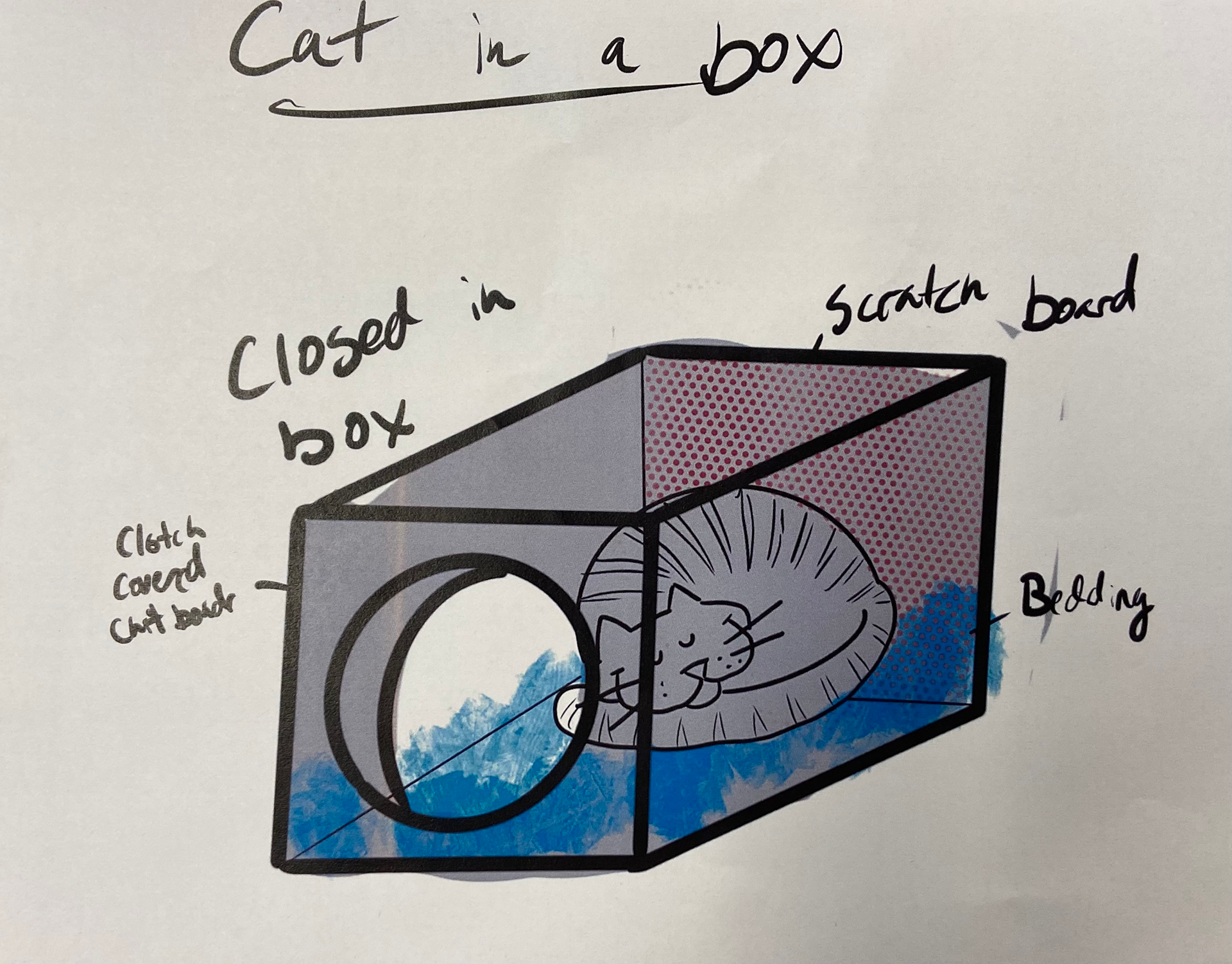

Ideas and sketches were eliminated and further pursued until we were down to three ideas

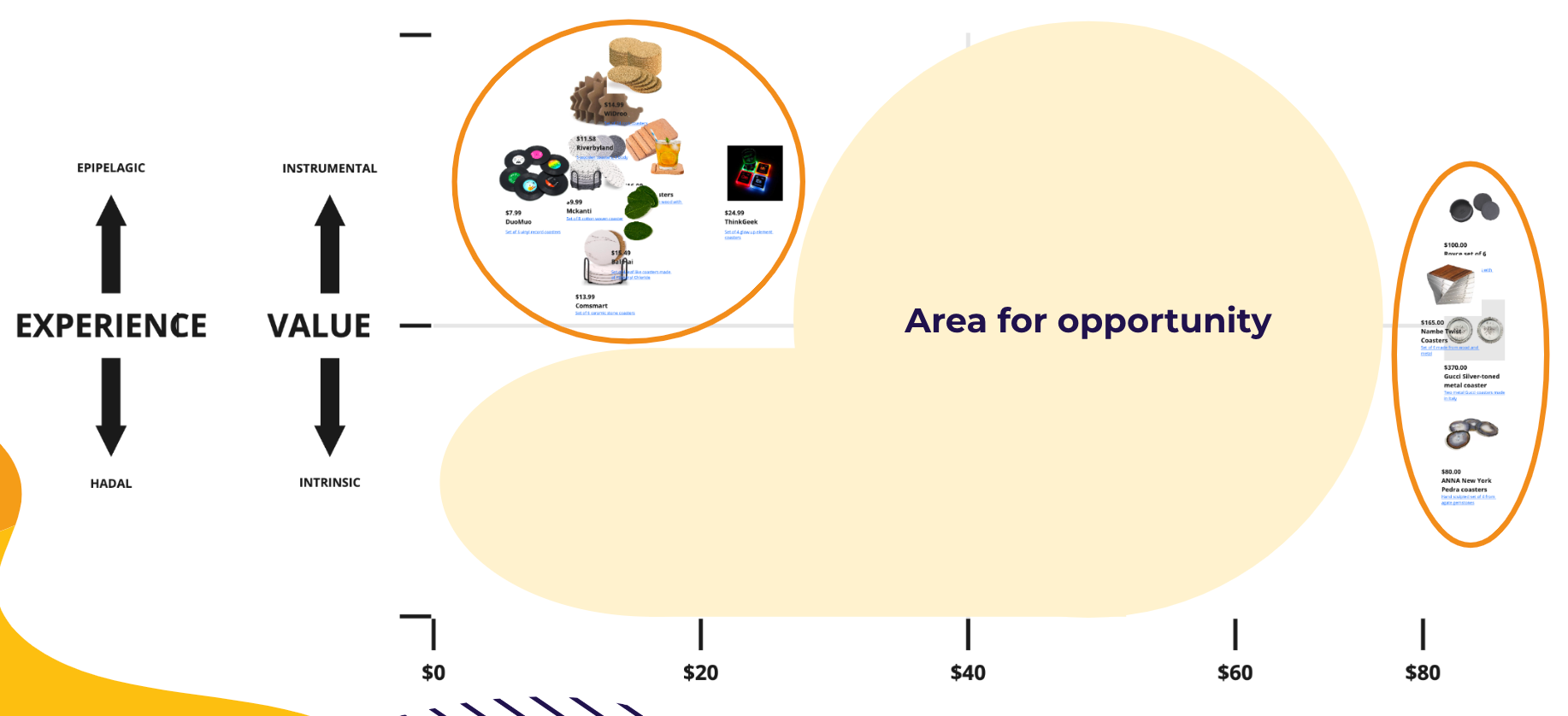

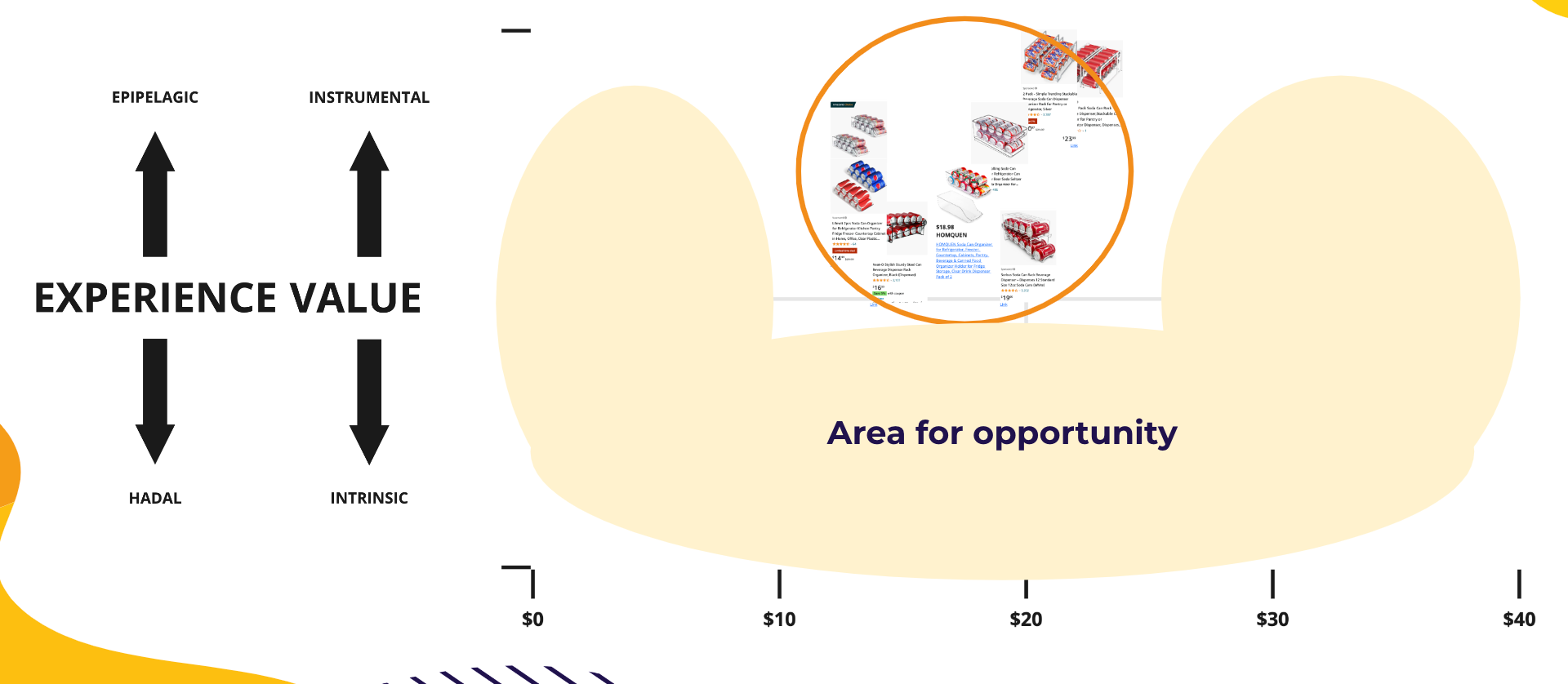

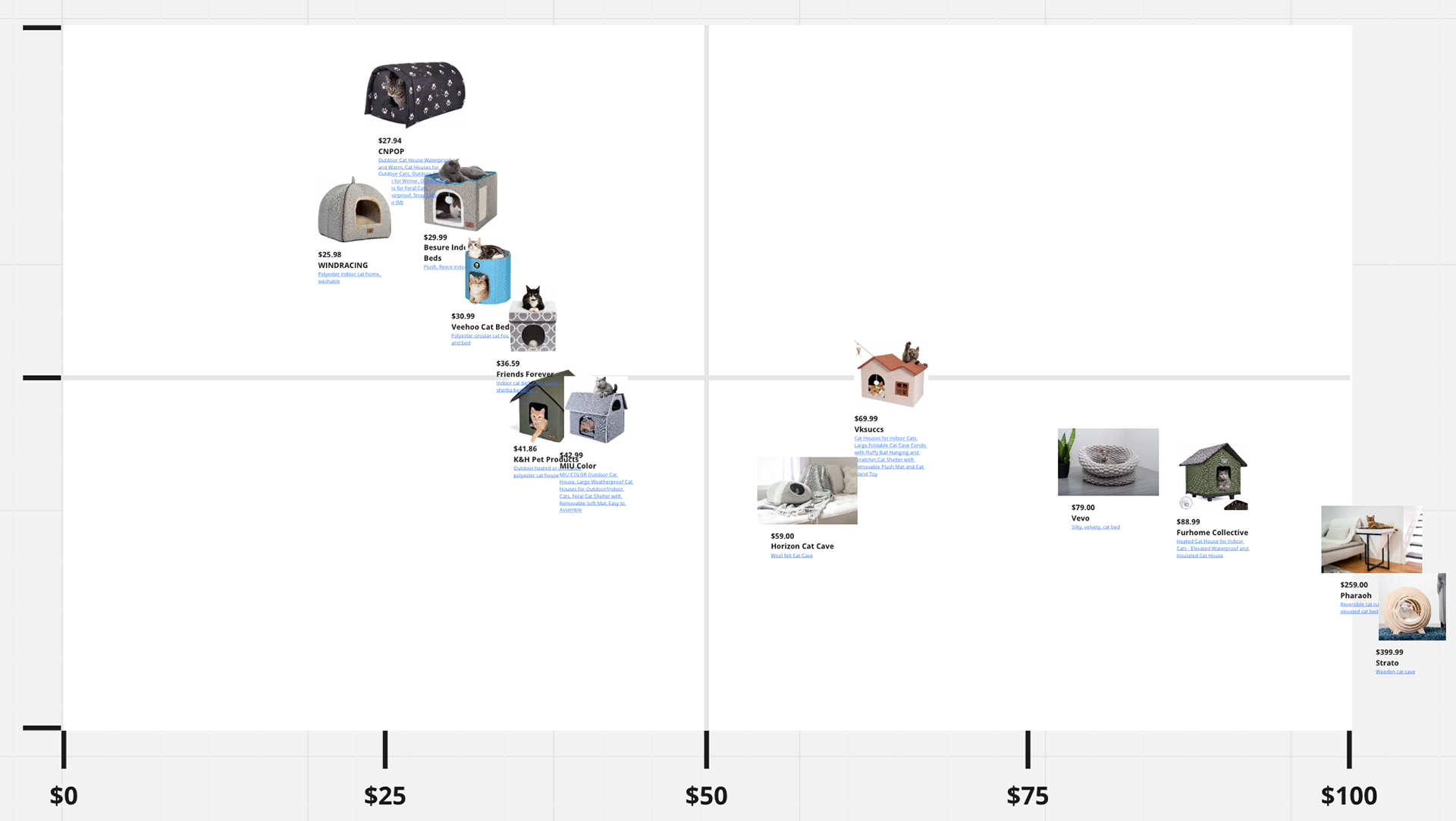

With three ideas that are starting to become solidified, market analysis were done for what these items would like look in the most comparable market

Finally, the final two ideas were settled upon and a presentation was created to weigh both of their concepts, prototypes, visuals, sustainability, connections to research, their budgets, and so on

Phase Three: Develop & Deliver - Duration: Four weeks

Tools Used: Woodshop machinery, sanding, painting, finishing, material testing

After presenting, a final concept was decided on, coasters were the route the group was heading down and it was time to pick up where they left off with the prototypes. We first developed a brand with patterns, logos, and a name, so we decided to test four different models. Two that are stained, one with a pattern, one without, and two without stain, one with a pattern, one without one

The group decided on the coasters that were stained and had no pattern on them. It was now time to begin manufacturing 40 coasters to make up the 10 sets of four. The process of cleaning up the wooden beams first goes through a bandsaw to make all of the slates around 1/2 an inch thick. A rotary saw was used to cut the wooden slates down to 36 inches long so they would fit within the laser cutter. Then they were a planar sander and a giant sand belt to get all the pieces to a 3/8 inch thickness. Then they were sanded using 180 grit and 250 grit before being put into the laser cutter

After laser cutting the coasters out the process of refining, the product began. They were all hand sanded, both faces, interior and exterior edges along with the sides. After the first round of sanding, the wood stain was able to be applied for a first coat and after two hours a second coat was able to be applied.

After staining another quick round of hand sanding took place and it was the coasters were ready for painting

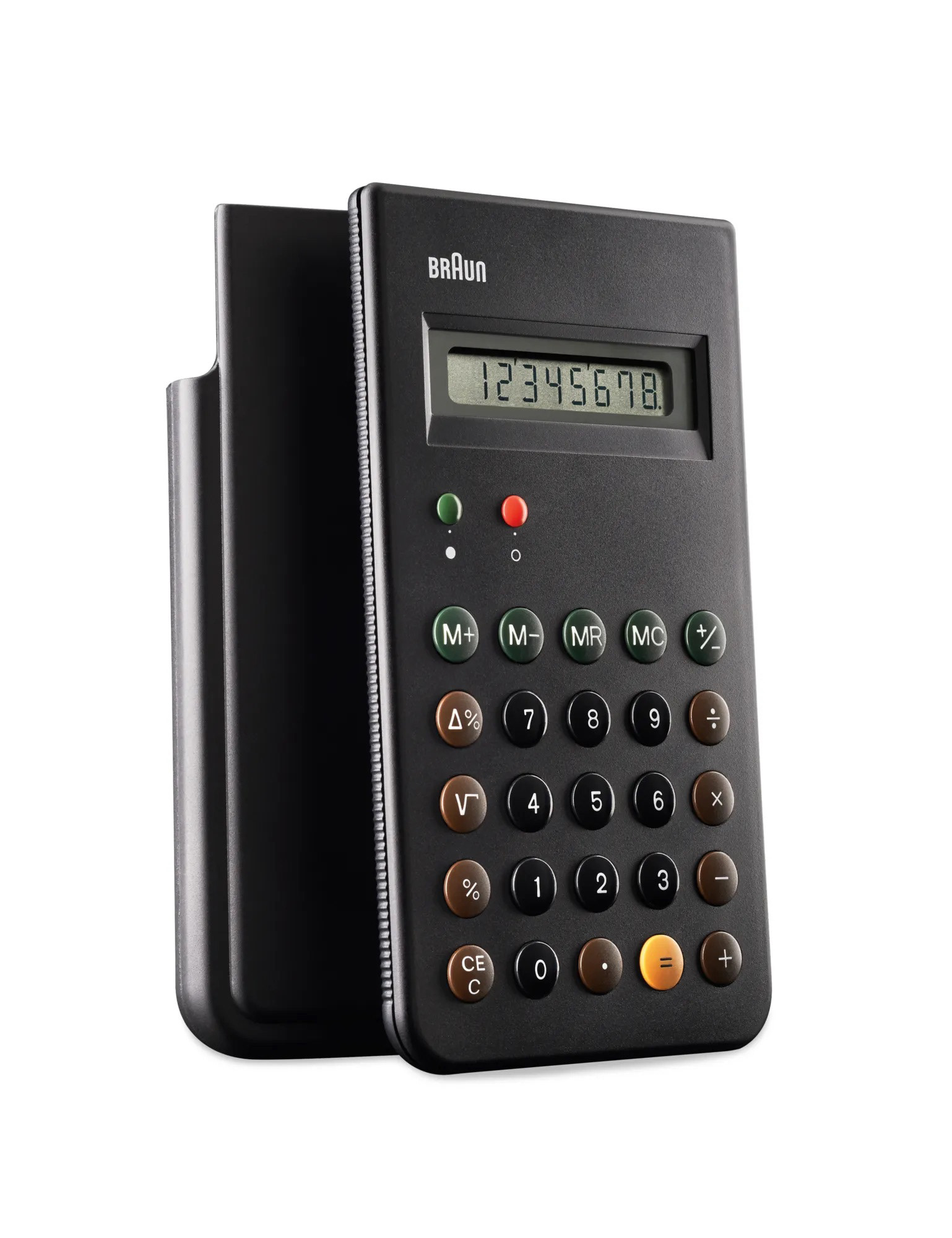

The color palette was inspired by late Braun calculators

The coasters went through multiple coats of paint using tape to get crisp lines between the striped design and the side of the ring. After painting it was time to put on a coat of linseed oil finish and prepare to present a final product at our own Winter Market

Continually through the coaster process, simultaneously a process was going on behind designing a stand that acts as a ring toss game for the coasters as well. Originally it was going to be 3D printed, but after modeling one it decided it looked tacky. Eventually, it was decided it would be made of wood, with circular bases, a dowel rod stand, with a 3D-printed painted cap on top to match the color palette of the coasters

After months of researching, developing, and crafting the group had finally conceived a product they were proud of and created a buying experience where they were able to sell all 10 sets of their coasters at Ohio State's annual Winter Market. The group raised $250 dollars from their product by selling each set of coasters with a base at $25 a piece.